In an era where technology evolves at lightning speed, Industry 4.0 is paving the way for advancements. Embracing these changes isn’t just an option; it’s a necessity. Whether you’re an engineer or technician, understanding Industry 4.0 is crucial for staying relevant in today’s competitive job market.

1. Understanding the Core of Industry 4.0

Industry 4.0, often referred to as the Fourth Industrial Revolution, integrates advanced technologies like IoT, AI, and big data. Knowing how these components interconnect is key for engineers and technicians looking to innovate within their fields. This digital transformation is enabling factories to become smarter and more self-sufficient, creating a seamless blend of physical and digital worlds. By harnessing the power of these technologies, industries can achieve unprecedented levels of flexibility and customization.

More than just a technological upgrade, Industry 4.0 represents a shift in how industries operate. The integration of systems ensures that information flows freely between all parts of a business, from the shop floor to the top floor. This allows for changes to be implemented quickly and efficiently, driving competitiveness and reducing time to market. As engineers and technicians, the knowledge of integrating such systems isn’t merely beneficial—it’s invaluable in fostering innovation and efficiency.

2. The Role of Automation and Robotics

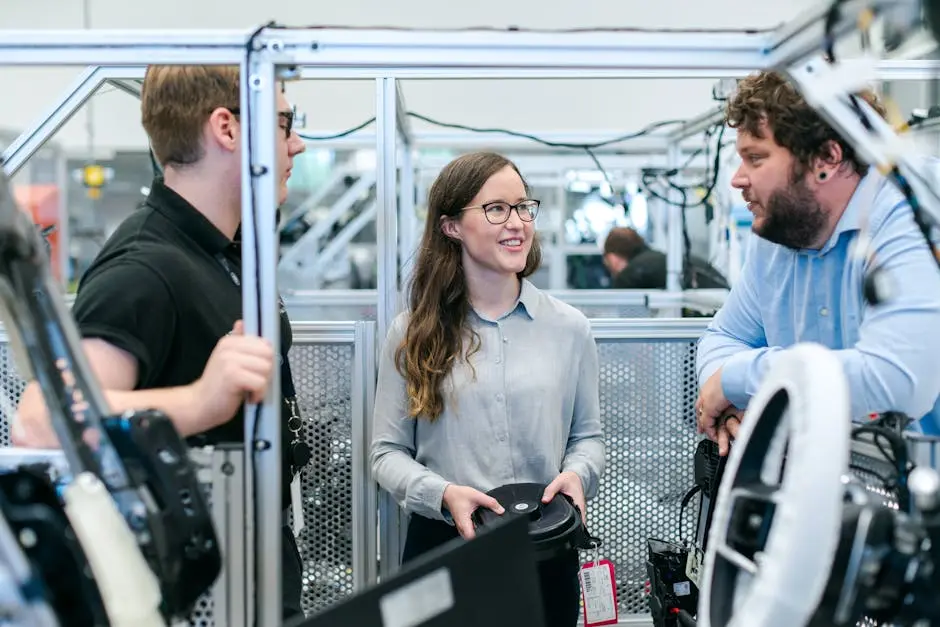

Automation and robotics are at the heart of Industry 4.0. Engineers and technicians who understand how to implement and optimize these technologies will be pivotal in increasing efficiency and reducing operational costs. Robots today are not just confined to repetitive tasks; they’re increasingly intelligent, capable of making decisions or changes in real-time when the environment changes. This capability drastically reduces wastage and increases uptime, fostering a culture of efficiency and effectiveness in production environments.

Moreover, the implementation of robotics doesn’t only scale productivity but also redefines worker safety. Robots can handle hazardous tasks, thus drastically reducing workplace injuries. They allow human workers to focus on more complex and meaningful aspects of production. This symbiotic relationship between humans and machines is a key facet of modern manufacturing, empowering engineers with the tools they need to create more agile and responsive production systems.

3. Data Analysis and Its Impact

Data is the new oil in the realm of technological advancement. Engineers and technicians equipped with data analytic skills can turn raw data into actionable insights, driving smarter decision-making processes. A thorough understanding of data analytics allows for the enhancement of operational performance and the optimization of asset utilization. In industries where the margin for error is slim, such insights can be the difference between profitability and loss.

Furthermore, data analysis supports predictive maintenance—a methodology that underpins many Industry 4.0 implementations. Rather than waiting for machinery to fail, predictive analytics uses data to forecast problems, allowing for maintenance to be executed proactively. This results in reduced downtime and increased machine lifespan, which are vital for maintaining competitive advantage. Engineers and technicians, by harnessing these skills, can significantly reduce costs while maintaining high service levels.

4. Cybersecurity in the Age of Connectivity

With increased connectivity comes the risk of cyber threats. Understanding the principles of cybersecurity is essential for protecting sensitive data and maintaining system integrity within Industry 4.0 environments. As more devices connect to networks, the potential for cyber interference grows, posing risks to operational safety and data privacy. Cybersecurity expertise is essential to build resilient systems that safeguard against breaches and ensure stable industrial operations.

Engineers and technicians well-versed in cybersecurity can ensure that all connected devices are protected against malicious attacks. This involves not just securing devices, but also encrypting data and creating robust access controls. In essence, securing Industry 4.0 initiatives requires a holistic approach that covers every layer of networked communication and data processing, making the work environment safer and more responsive.

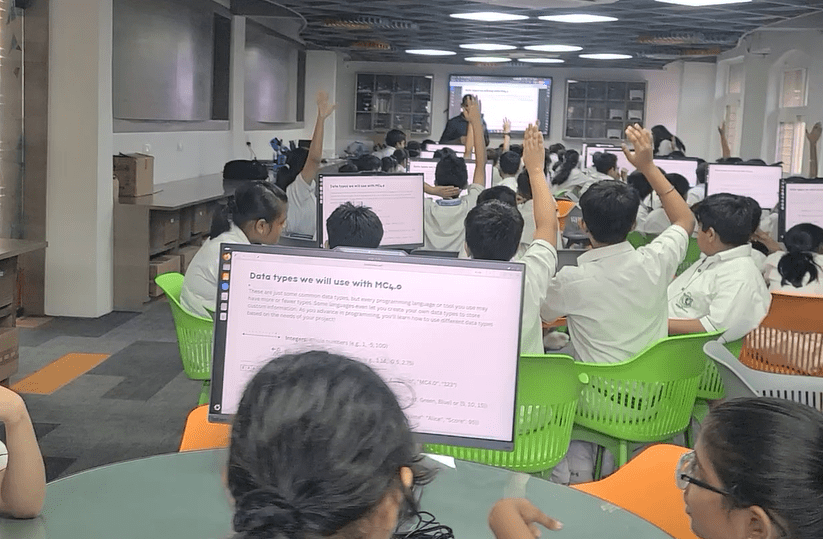

5. The Importance of Adaptability and Continuous Learning

As technologies evolve, so too must the skills of engineers and technicians. Cultivating a mindset of adaptability and committing to lifelong learning are essential to thrive in the ever-changing landscape of Industry 4.0. Staying updated with the latest advancements ensures that engineers can leverage new tools and techniques effectively. This continual education enables technicians to troubleshoot emergent issues and innovate solutions that enhance operational efficiencies.

In the fast-paced world of Industry 4.0, change is the only constant. Those who embrace change and continuously learn new skills will find themselves at the forefront of industrial evolution. Educational platforms and immersive training solutions are becoming increasingly important, providing up-to-date resources to support this ongoing learning journey. Investing in education not only future-proofs individual careers but also strengthens the industry’s ability to tackle future challenges head-on.

For further details on equipping with these critical skills, visit Ednex to explore Industry 4.0 aligned training programs designed to enhance the skill sets of modern engineers and technicians, ensuring they remain competitive and innovative.

No comment