Control engineering is a vital field that ensures systems behave in the desired manner. Whether it’s in manufacturing, aerospace, or other industries, control engineering plays a key role in maintaining stability and efficiency. Let’s dive into what control engineering is all about and why it matters.

Defining Control Engineering

Control engineering is a fascinating discipline that anchors its principles in physics, mathematics, and engineering to create systems that can control the behavior of devices and processes. It is integral in industries ranging from aerospace to consumer electronics. In essence, control engineering seeks to make devices operate automatically and efficiently, minimizing the need for human intervention. By employing feedback loops and rigorous mathematical modeling, control engineers are able to maintain the stability and performance of complex systems, whether by regulating a car’s cruise control or maintaining the climate within a space station. The core objective of control engineering is to achieve desired outcomes consistently, under varying conditions, making it an indispensable field in today’s technology-driven world.

At the heart of control engineering lies the development of algorithms and models that predict system behavior. In the design process, engineers often use tools such as state-space representation and transfer functions to map the dynamics of systems. This enables precise adjustments in the input to achieve the desired output, making it possible to automate processes like temperature control, flight stabilization, and even industrial robotics. Through continuous advancements and integration with technologies like the Internet of Things (IoT) and machine learning, control engineering is breaking new ground in creating smarter, more responsive systems.

The Role of Feedback in Control Systems

In control engineering, feedback mechanisms play a central role by using the system’s output to adjust the input, thus maintaining desired operational conditions. This iterative process forms the backbone of many control systems, enabling them to adjust automatically to changing conditions without manual intervention. A classic example is the PID controller used extensively in industrial control systems. This controller continuously calculates an error value as the difference between a desired setpoint and a measured process variable, applying corrections based on proportional, integral, and derivative terms. This methodology ensures precision in achieving targeted outcomes, such as maintaining specific temperatures in a furnace or managing the speed of motors in automotive applications. By analyzing real-time data and providing corrective feedback, control systems ensure stability and improve the efficiency of myriad processes across industries.

Feedback control systems are considered smarter than traditional open-loop systems because they can respond to unpredicted changes in the environment. For instance, in heating, ventilation, and air conditioning (HVAC) systems, feedback loops regulate temperatures by comparing the current room temperature with a set value and adjusting the heat output accordingly. This dynamic adjustment is crucial for maintaining comfort and energy efficiency. Understanding feedback’s role in control systems highlights its importance in achieving reliable and adaptable solutions in technology.

Applications of Control Engineering

The applications of control engineering span a multitude of sectors, each harnessing the ability of control systems to automate, optimize, and secure operations. In the automotive industry, for example, control engineering is pivotal in developing sophisticated electronic control systems that enhance vehicle performance and safety. From ensuring optimal fuel injection to regulating speed and maintaining vehicle stability, control systems play a vital role in modern automotive technologies. The aerospace industry also heavily relies on control engineering, where it is used to manage aircraft stability and navigation, making modern air travel both safer and more efficient.

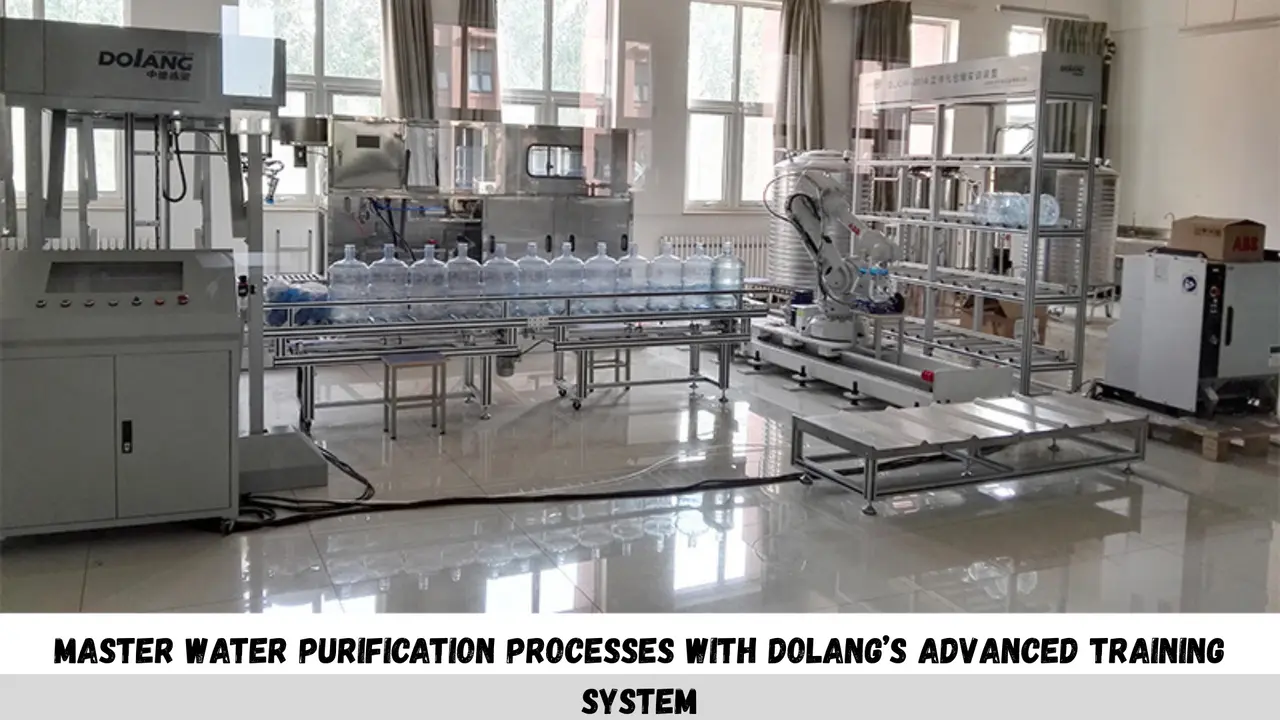

Beyond transportation, control systems are key in manufacturing processes where they ensure precision and efficiency. By automating tasks such as assembly, material handling, and packaging, control engineering minimizes human error and increases production capacity. This automation is not just limited to high-speed assembly lines but extends to industries like pharmaceuticals, where the accuracy of control systems in managing chemical processes is critical to product safety and efficacy. The future of manufacturing lies in even more advanced, interconnected control systems that promise to enhance efficiencies and productivity further.

Key Techniques in Control Engineering

Fundamental techniques used in control engineering are essential for creating systems that can manage complex tasks and operations with minimal human intervention. PID controllers are the cornerstone of control systems, effectively managing processes by fine-tuning the proportional, integral, and derivative gains. This fine-tuning ensures the system can adapt to changes and maintain the desired level of performance. State-space modeling is another vital technique, providing a mathematical framework that represents complex systems as a set of input, output, and state variables, capturing the system dynamics effectively.

Control engineers are also well-versed in advanced techniques, including adaptive and robust control, which allow systems to remain fault-tolerant under uncertainties or variations in system parameters. With the integration of machine learning and artificial intelligence (AI), control systems are capable of predictive analytics and smarter decision-making, vastly improving their scope and efficiency. These growing methodologies showcase the dynamic nature of control engineering and its pivotal role in developing cutting-edge technologies.

The Future of Control Engineering

The future of control engineering holds immense potential as it continues to integrate with emerging technologies to form the backbone of the next industrial revolution. With the growing presence of the Industrial Internet of Things (IIoT), control systems are set to become even more interconnected and intelligent, enabling unprecedented levels of automation and efficiency. The integration of control systems with cloud computing and AI is opening new frontiers, allowing businesses to optimize operations and predict maintenance needs before they arise. This predictive capability contributes to significant cost savings and operational resilience.

Furthermore, the push towards sustainable and renewable energy sources presents new challenges and opportunities for control engineers. As the world shifts to more eco-friendly energy solutions, control engineering will play a crucial role in managing these new energy systems. By ensuring they operate efficiently and reliably, control engineers will help drive the transition towards a more sustainable future. In summary, as control engineering evolves, it promises to offer innovative solutions that address both industry needs and global challenges, making it an exciting field with limitless possibilities.

Wrapping Up Our Exploration of Control Engineering

In summary, control engineering is all about designing systems that behave predictably and optimally. It’s a fascinating field that blends theory with practical applications to solve real-world problems. Understanding its role and its techniques opens up a world of possibilities in various industries.

Leave A Comment