Introduction

Water purification is critical in industries like pharmaceuticals, food & beverage, and healthcare, where high-purity water is essential. However, operating and maintaining industrial water treatment systems requires specialized expertise. Traditional training methods often fall short in preparing professionals for real-world challenges.

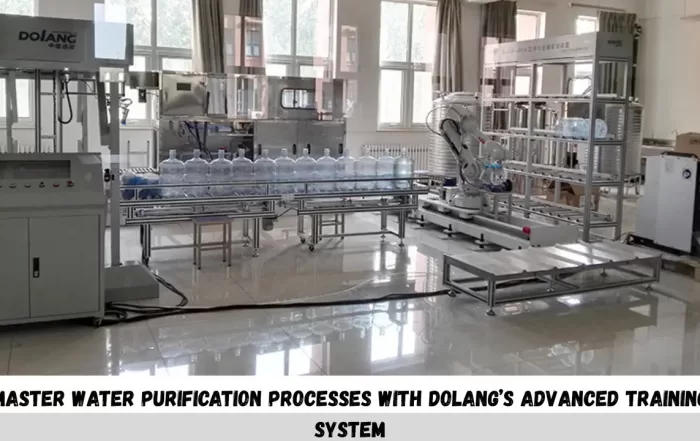

Dolang’s Purified Water Production Line Engineer Training System bridges this gap by offering hands-on, simulation-based learning. This advanced water purification training system equips engineers and technicians with the skills needed to optimize water treatment processes efficiently.

1. Understanding Water Purification Processes

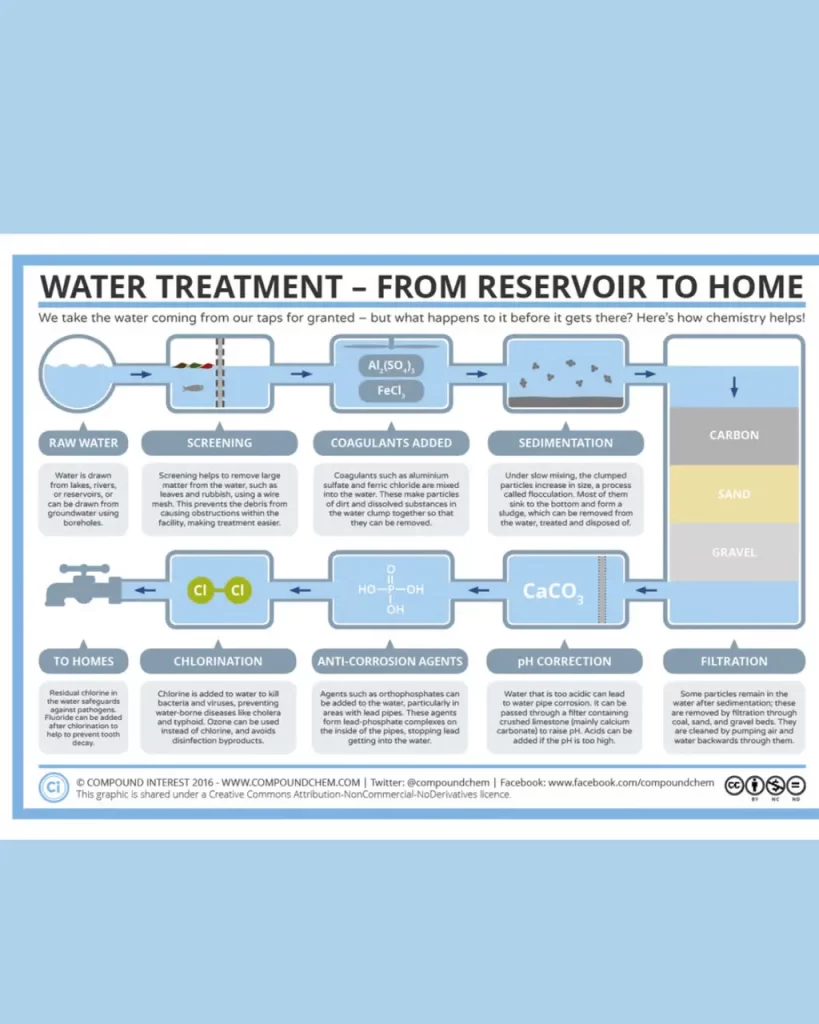

Water purification involves multiple stages, including:

- Reverse Osmosis (RO) – Removes dissolved salts and impurities.

- Distillation – Produces high-purity water through vaporization.

- Ion Exchange – Softens water by replacing unwanted ions.

- UV Sterilization – Eliminates microorganisms.

Industries rely on these methods to meet regulatory standards. However, improper handling can lead to contamination or system failures. This is where structured industrial water treatment training becomes crucial.

2. The Need for Specialized Training in Water Purification

Many professionals lack practical experience in troubleshooting water purification systems, leading to:

- Higher operational risks (e.g., membrane damage, bacterial growth).

- Increased downtime due to inefficient maintenance.

- Compliance failures in regulated industries.

Hands-on training reduces these risks by familiarizing trainees with real-world scenarios before they enter the field.

3. Introducing Dolang’s Purified Water Production Line Engineer Training System

Dolang’s water purification training system is designed to replicate industrial environments, offering:

Key Benefits:

- Faster Skill Development – Reduces the learning curve for new engineers.

- Cost-Effective Training – Eliminates the need for expensive on-site training.

- Improved Troubleshooting – Trainees practice fixing common system failures.

Explore Dolang’s Training System Here

4. How the Training System Works

The industrial water treatment training program follows a structured approach:

- System Setup & Safety – Learn proper installation and safety protocols.

- Hands-On Operation – Adjust flow rates, monitor TDS levels, and optimize filtration.

- Fault Simulation – Practice resolving issues like pump failures or membrane fouling.

- Data Analysis – Generate reports to ensure water quality compliance.

This method ensures trainees gain confidence in managing real-world water purification systems.

5. Who Can Benefit from This Training System?

- Engineering Students – Gain practical skills for careers in water treatment.

- Plant Operators – Improve efficiency in daily operations.

- Quality Control Teams – Ensure compliance with industry standards.

- Vocational Trainers – Enhance teaching with interactive modules.

6. Why Choose Doolang’s Solution Over Conventional Training?

Feature

Traditional Training

Doolang’s System

Hands-On Practice

Limited

Extensive

Fault Simulation

Rarely Available

Built-In

Cost Efficiency

High (on-site training)

Low (reusable system)

Companies investing in this water purification training system see a faster ROI through reduced downtime and improved workforce competency.

Conclusion

Mastering industrial water treatment requires more than theoretical knowledge—it demands hands-on experience. Doolang’s training system provides a realistic, risk-free environment to develop essential skills efficiently.

Ready to upgrade your team’s expertise?

No comment